CONTINUOUS IMPROVEMENT

Over 30 years as a leader in continuous improvement.

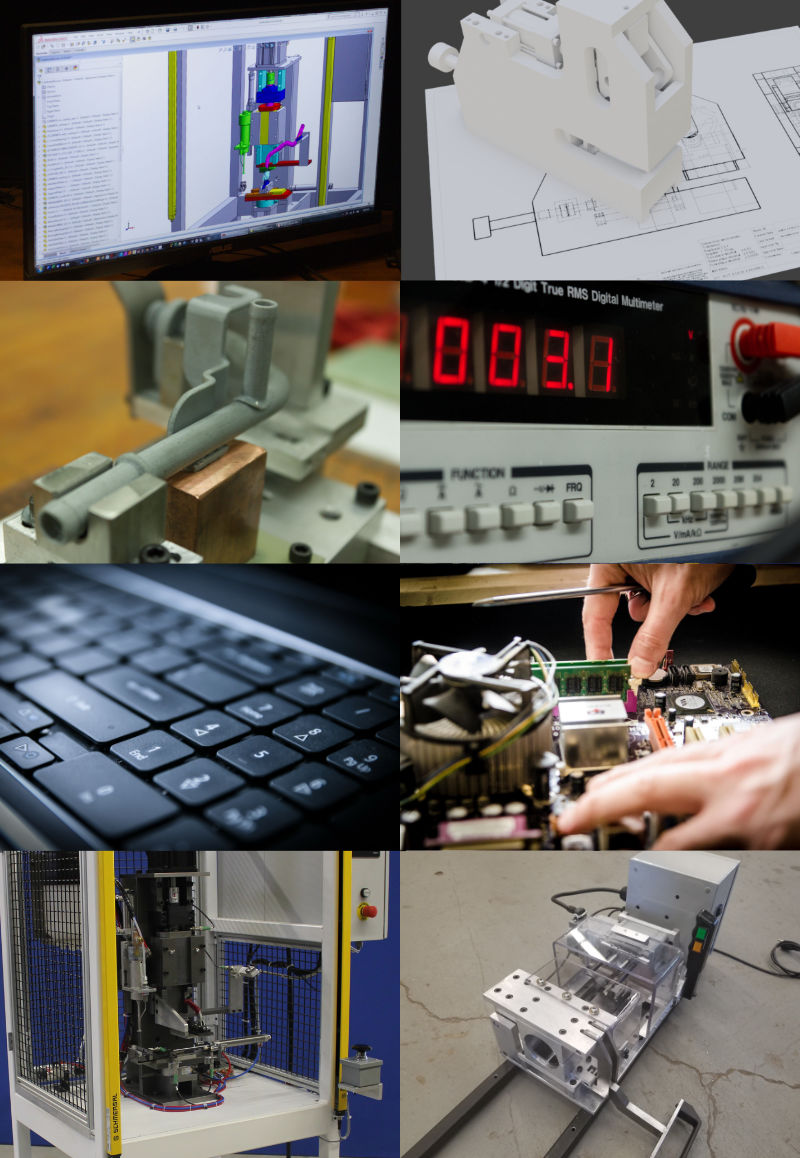

FABRICATION AND PROTOTYPES

Prototypes, mock-ups, test fixtures and short run manufacturing.

TRAINING AND DOCUMENTATION

Documentation, user instructions, training materials, illustrations, and drawings.

Over 30 years in the business of creativity, problem solving and continuous improvement expertise.

Our goal is to be a resource to help you develop your ideas, make improvements to your products and processes, and create products that help ensure quality and improve efficiency.

DESIGN AND VISUALIZATION

Computer Aided Design, concept sketches, artist renderings, 3D animations, photo-realistic renderings, idea generation to help you develop and get your ideas across.

TECHNICAL WRITING

Technical writing for presentations, training manuals, user and operations manuals, maintenance instructions, sales copy help, etc.

MECHANICAL AND ELECTRONICS FABRICATION

Full fabrication capabilities, 3D printing, custom electronic circuit boards, enclosures, assembly, panel building, manufacturing services and complete prototype manufacturing.

PROGRAMMING

Embedded and desktop systems, micro-controllers, database, website and app development, PLC programming. Languages include C, C++, Python, Django, Javascript , React, HTML, CSS, etc.

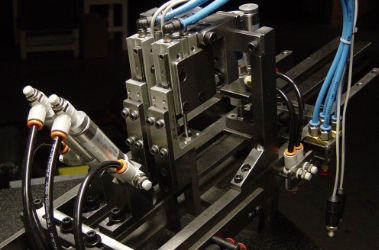

FIXTURES AND AUTOMATED EQUIPMENT

Quality inspection and assembly fixtures. Automated quality control and testing. Online retro-fit or offline standalone testing. Custom automated machines for assembly and automation retro-fits on existing machines.

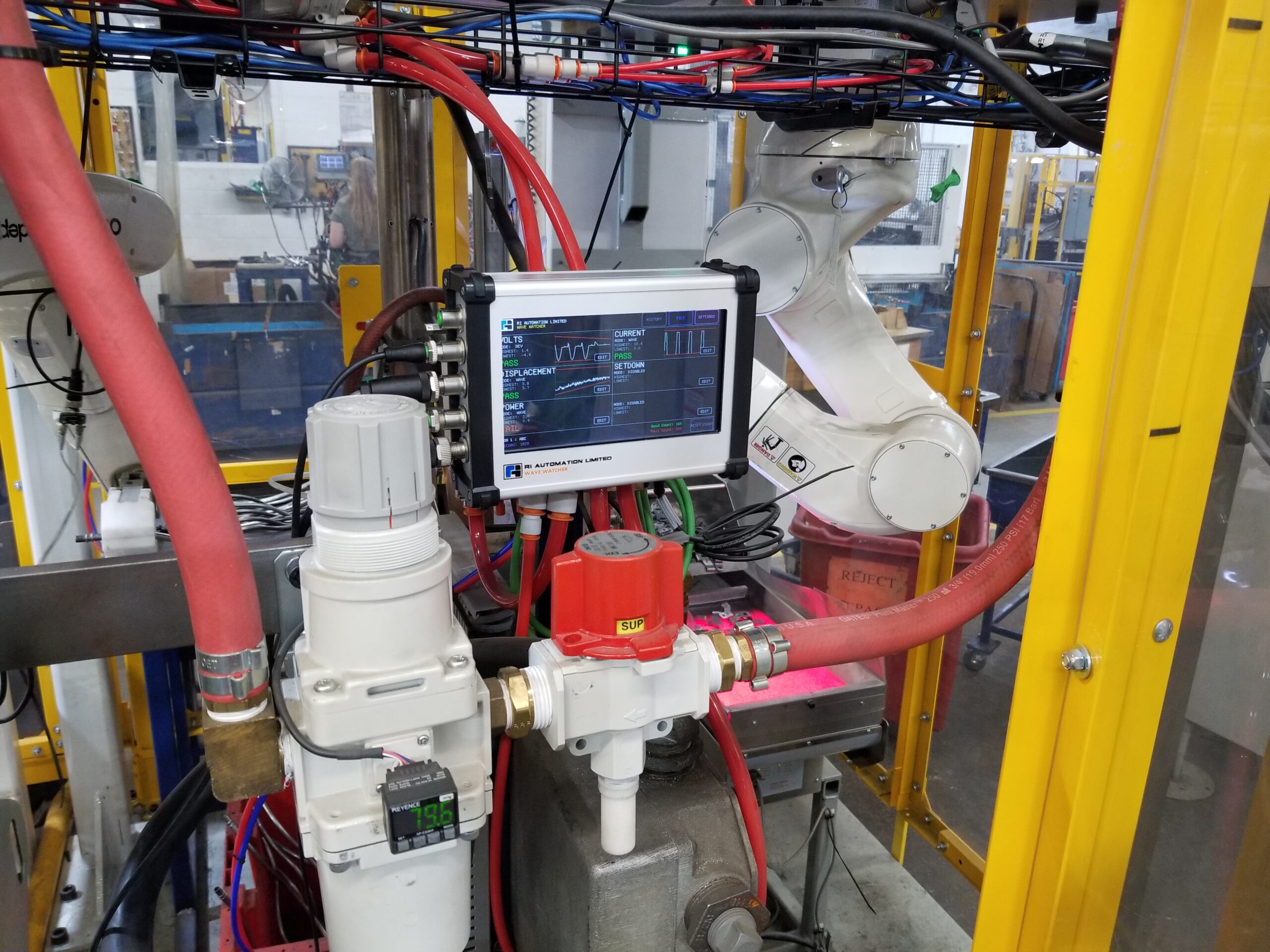

PROCESS MONITORING, IOT AND CUSTOM ELECTRONICS

Monitoring equipment for leak testing, welding, environment monitoring, etc. Our DTA Symphony service is a full featured online productivity and analysis tool.

Some of Our Success Stories

Examples of the ways we have helped our clients increase productivity and quality.

Robot Weld Cell Productivity and Quality Improvements

Doubled production while reducing manpower requirements by 33% through modifications to robot programming, weld cell layout for better ergonomics and material flow and improvements to upstream operations.

Automated Inspection Eliminating Extra Work and Ensuring Quality

A tier one automotive supplier needed to ensure all their finished parts all met the proper specifications. An automated Go-No Go gauge system was added to the press output which checked every part, dropping any non-conforming parts in a reject container.

Grommet Installation Tool Drastically Increasing Productivity

This client needed to insert rubber grommets into holes in a bracket. Requirements did not warrant automation, so we developed a manual tool. Productivity was drastically increased and risk of repetitive injury to the operator greatly reduced.

Projection Welder Monitor Ensuring Consistency and Quality

This client needed an economical and reliable method of monitoring their projection welding process. We developed the Wave Watcher product, which gives them the tool they need to ensure quality welds on every part.

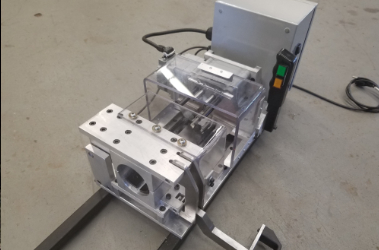

Cap Installation Fixture Increasing Efficiency and Reducing Injury

A large plastic cap was being installed manually by this client, causing a strain on the operators. We built them a semi-automated installation tool utilizing an adjustable torque brushless motor saving operators from injury and increasing productivity.

Some of Our Clients

We don’t stop until you are happy. Contact us today.